- Description

- Performance

- Parameters

- PDFdownload

- Contact

-

(1) Very good cutting quality: suitable for cutting pipes of various materials. The entire cutting process is cold cutting, without burrs. The cut end face is 100% vertical, and can be directly welded. The cutting process does not require coolant, and the parts to be welded on the pipes are not contaminated, ensuring welding quality.

(2) Very high cutting speed: This machining method can complete the cutting of a stainless steel pipe with a diameter of 88.9mm * 3.05mm (wall thickness) in 30 seconds.

(3) Overall compact and portable: The machine structure is compact and convenient to carry, making it very suitable for project site and factory workshop operations.

(4) The cutting machine features a small clamping distance between the cutting blade and the pipe, only 13.5mm, to avoid vibration during cutting, high cutting accuracy, and long blade service life.

(5) Set up concentric circle fixtures to avoid deformation of pipes during clamping. The global patent for concentric circle fixtures ensures higher cutting and groove efficiency accuracy. Other brands use symmetrical clamping solutions, which can easily deform thin-walled pipes and affect groove accuracy.

(6) Rotary wheel cutting makes cutting easier and more labor-saving, with uniform speed, thereby increasing the service life of the blade.

CT-4 (BE13) Cutting thickness0.5-3mm

CT-6.5(BE13) Cutting thickness0.5-3mm

CT-8.5(BE13) Cutting thickness0.5-3mm

CT-4(MS18)Cutting thickness0.5-6mm

CT-6.5(MS18)Cutting thickness0.5-6mm

CT-8.5(MS18)Cutting thickness0.5-6mm

Automatic cutting through the optional public transportation system

选配坡口机头

选配CT-10机头可与CT-4/6.5/8.5机座匹配轻松实现坡口

坡口:●增加一个高速坡口电机,CT-10即可坡口斜边V型30度、37.5度、45度,以及U型坡口10度,坡口速度快。

CT-10的技术参数

Groove pipe wall thickness

Power

Voltage

Revolution

<8mm

1500W

220V

2500-7500RPM

The following figure shows the dedicated groove motor CT-10

CT series beveling machine

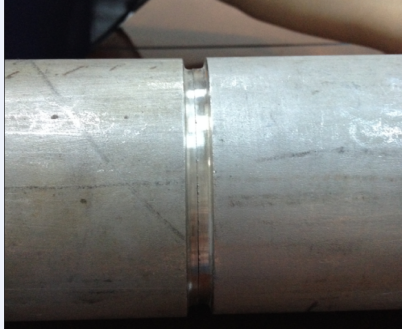

The groove effect can achieve a mirror effect, as shown in the following figure:

The left image shows a V-shaped groove, while the right image shows a U-shaped groove of 10 ˚ The U-shaped groove effect (as shown in the figure) is conducive to automatic welding.

Auxiliary tool bracket series: Support both ends of the pipe during cutting to prevent it from falling off. A single bracket is 1.5 meters long, and it is recommended to use three to four brackets when cutting six meter long pipes.

-

-

Model

Cutting range

Weight

CT-4

5-120mm

37KG

CT-6.5

16-170mm

47KG

CT-8.5

60-220m

51KG

-