- Description

- Performance

- Parameters

- PDFdownload

- Contact

-

ARC 200P digital welding controller is designed and manufactured by our company specially for the latest development, design and manufacture of thin-walled sanitary pipe/tube butt joint welding in the installation industry. It is an advanced automatic program-controlled welding Powersource, which can be used with a closed welding head. It is equipped with a water-cooling system as standard. It is mainly used in food machinery, on-site installation of pharmaceutical machinery, micro-electronic pipelines, semi-conductor pipelines and laboratory pipelines.

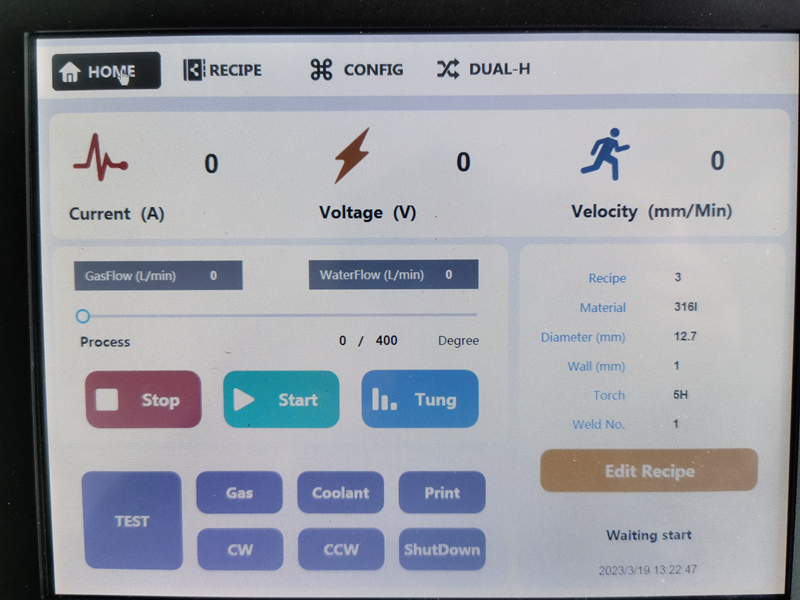

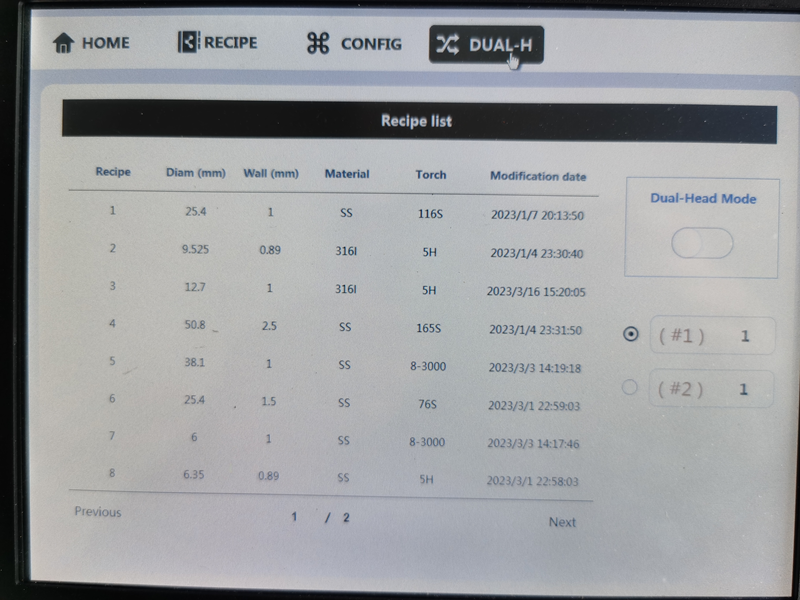

Operating System Interface

Functions and Features

²

Small size, light weight 24KG, easy to carry;

²

Full size touch screen, using Chinese, English, Russian operation interface, more convenient operation

²

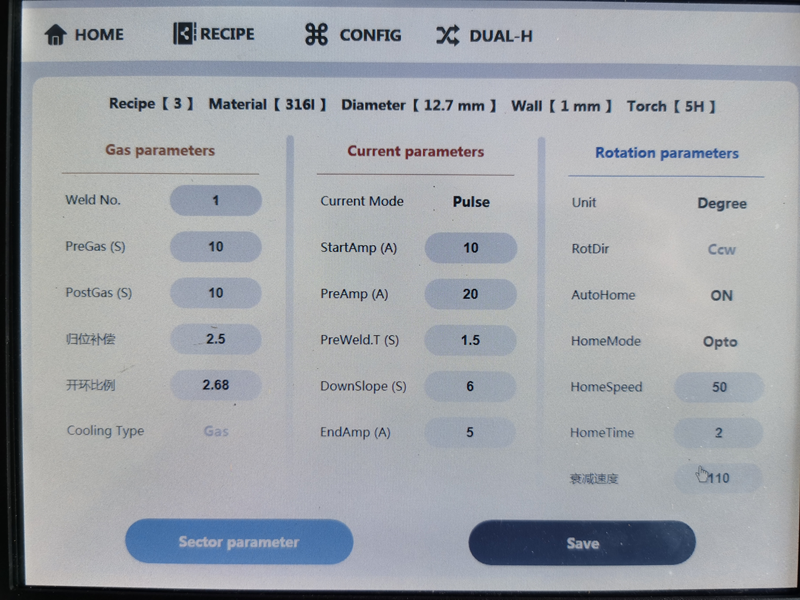

Automatically calculate expert parameters, more convenient and quicker to find suitable welding parameters

²

Able to store 999 sets of programs to meet the different needs of different customers

²

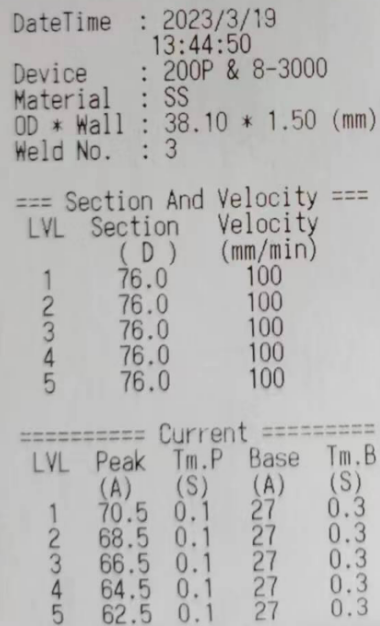

Powerful multi-sector function, max. number of sectors can reach 20, and the change of interval parameters can be gradually changed according to the process requirements;

²

Input voltage 220V, suitable for more construction sites

²

The arc characteristics are straight and strong, which can be adjusted according to different materials

²

Lack of gas protection function (alarm when the air flow is lower than 3 l/min)

²

Water shortage protection function (limit start when the water flow is not enough and the water temperature is too high)

²

Overvoltage and undervoltage protection function (limit start-up when the supply voltage is too high or too low)

²

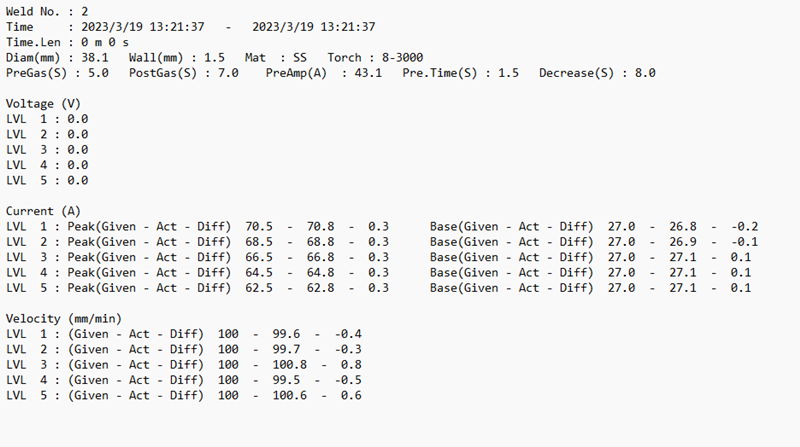

Closed-loop control, current and welding speed automatic compensation difference

²

DSP chip control. More precise, faster response

²

The water-cooling system is automatically adjusted according to different weld heads

²

Status Indicator. Can clearly judge the working status and prevent mis-operation

²

Automatic printing function, you can choose manual and automatic printing according to different needs

²

The U disk saves the welding port number parameters. Print welding parameters through common computers and printers (can be modified manually). Display the deviation between the actual welding value and the set value

²

Welding parameter patching printing function. Welding first, and reprinting welding parameters together in spare time

²

Homing uses optocoupler, code disc, time, mechanical methods. Even if the counting fails, the time can be used to weld smoothly, and the repair will be done after the project is over.

²

The machine core adopts independent channels. It is completely separated from the control part, which is beneficial to the heat dissipation of the movement and ensures the stability of the current output;

²

The air inlet of the movement channel is dust-proof. Prevent dust particles from entering the movement and prolong the service life.

²

Unique dual head mode. The control box can be added to connect two weld heads of the same type or different types at the same time to realize asynchronous welding of pipes of the same specification or different specifications. Doubling the utilization rate of the host controller

Print

Print with integrated printer in system language

Able to be saved in USB Drive, print to display the difference between the actual output value and the set value

-

-

Model

ARC 200P

Color

Red

Language

Chinese/English/Russian/Japanese

Type

Inverter

Control

Touch Screen + DSP control

Welding Current

3A-200A,

Min. Arc extinguishing current

3A

Response Time

0.001s

Power Input

220V(±10%),50/60HZ

Duty-Cycle(20℃,10min)

110A 100%

200A 60%

Floating Voltage

56V

Max. Power/Suggested Switch Box Specification

4.5KVA

Isolation / Protection Class

F/IP21S

Working Temperature

-10℃~+40℃

Cooling Method

Built-in Water Cooling

Display

10.4” Touch Screen

Printer

Integrated Printer

Controlling Function (4 axles)

Gas Control(ON/OFF)

External flow control box can be connected to realize automatic control of gas flow

Current Control

Rotation Control

Water Control

Max. Program Number

999

Max. Sectors

20

Coolant Tank Volume

1.6L

Dimension L/W/H[mm]

460*360*248

Weight(Without Coolant)[kg]

24kg

Manufacture Standard

GB15579.1-2013

Application Industries

Pharmaceutical machinery, food & beverage machinery, petrochemical, water treatment, electronics, semiconductor, military, aerospace

-

- Pre5H/10H

- NextFlat mouth machine series